Out of extremely wide range of stones that come from India and which have become popular all over the world, one of them goes by the name of Rainforest. In almost any stone stockyard anywhere in the world one will almost always find at least a few slabs of this attractive sandstone, though in true industry style, the name on the sticker may well be different. This article explains in more detail the complexities behind this stone much in demand.

Rainforest: name and varieties

Rain Forest would more accurately refer to a family of stones and not a particular shade in concrete since there can be wide differences from one slab to another. There are different varieties of Rainforest available in the market, but basically they can be divided into three varieties:

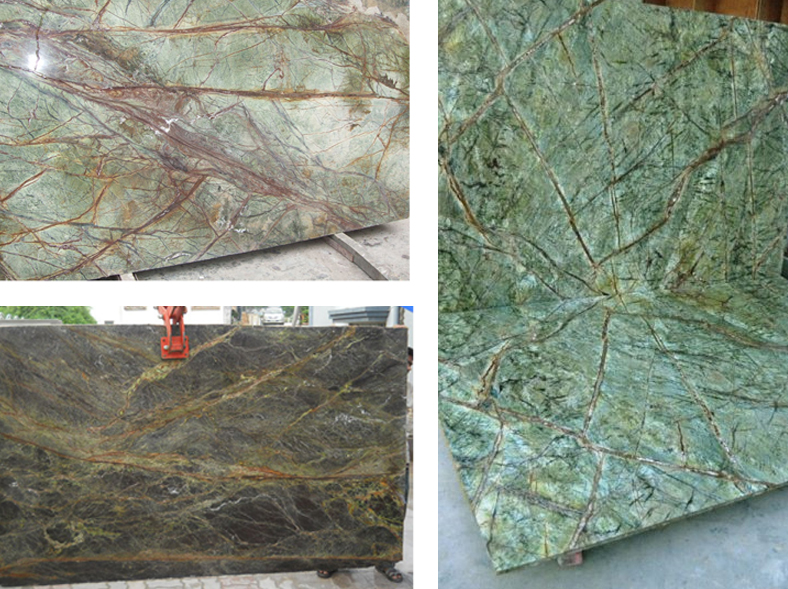

1 Green Rainforest

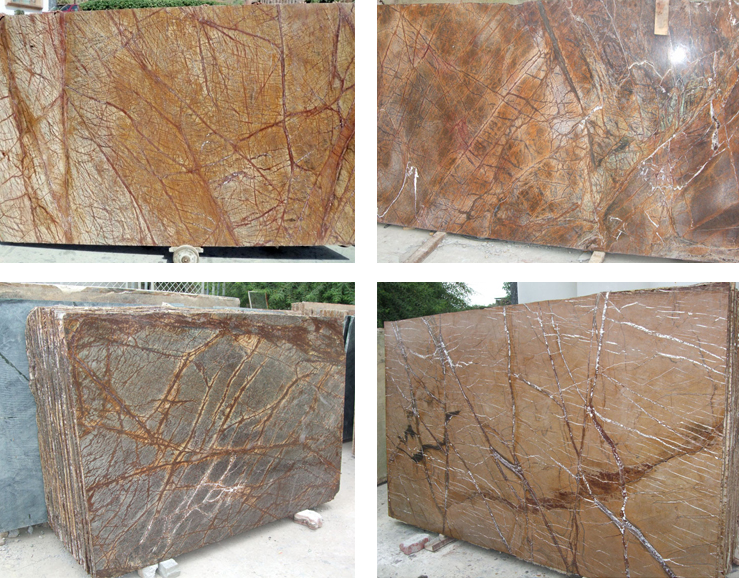

2 Brown Rainforest

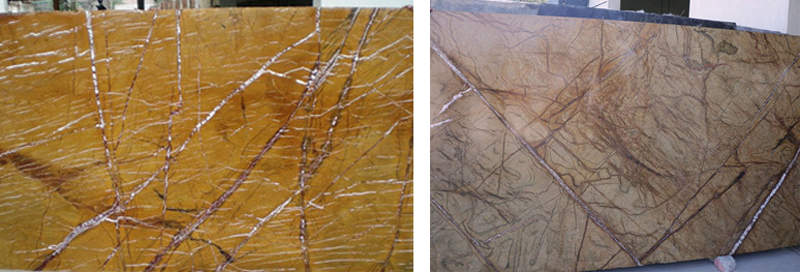

3 Gold Rainforest

In the market this stone is sometimes erroneously called marble, but in reality it is sandstone. The most common variety coming out of the quarries as of 2011 is of the Brown shade. However, the colour variation can change from rock to rock in a very unpredictable way. The veins also tend to vary-sometimes they can be thin and very light, and they can also be of bigger size and thick. Currently the Brown variety is the most in demand, followed by Gold, and then the Green variety.

Quarries and processing of Rainforest sandstone

The quarries are located in north Rajasthan in the village of Sujangarh. Exploitation of quarries began 20 years ago, and as of 2011 there are a total of 25 quarries of which around 12-15 mines are operating. The material is basically located in the 1st, 2nd, and 3rd level and after that there is nothing. Thus the life of the quarries is not estimated to be more than 10 years at current rates of extraction.

There are not more than 10 processing units of this material in Rajasthan and only about half of these are processing the stone with modern machinery. Total production is estimated to be around 2000 cubic metres per month. Around 1000 people depend on the extraction of Rainforest for their livelihoods.

Rainforest is a very hard material and there are a lot of natural cracks. Sawing is done be diamond gangsaws in India and the blocks exported to Italy are sometimes processed in sanded gangsaws. The slabs of Rain Forest need netting at the back and proper resin filling in the top surface.

Finishes and sizes

The polished finish and brushed finish (also called the Antique finish) are the most common. Stone with honed finish is also in demand in the market. Rainforest is available in big sized slabs and tiles. Typical slab size is around 270 x 150 cm. The thickness tends to be mostly 3 cm but 2 cm slabs are also available. Mosaic tiles are also usually supplied by the local manufacturers.

Applications

The low absorption level of Rainforest allows for wide application in exterior floorings. The material is in high demand in USA, Italy, Poland and Russia. As in the case of other materials, blocks are also being exported to China and Italy. The main shipping port is Mudra.

The biggest problem for the stone processors in India is the buyers’ expectations of a certain amount of uniformity, which is extremely hard to obtain in the case of Rainforest. Demand being high, supply limited due to the very nature of the quarries, and perhaps even more limited in terms of overall deposits, it comes as no surprise that Rain Forest enjoys a premium price in the world markets.

**Our thanks to Mukesh Kabra and Prabhat Jain for all information and help provided in the elaboration of this article.

Sections