Estefanía Fernández Prieto

Chemical Engineer, Technological Centre PINACAL INSER,Valladolid (Spain) laboratorio@pinacal.es

The environment presents an elemental functional duality- it is a source of resources and a drain for waste. The extraction and processing industries interact in a direct form with the environment. Below an analysis on sustainability in the process of extraction, transformation and transport of natural stone is presented, in a way that demonstrates both qualitatively and quantitatively, that natural stone is an excellent example of a sustainable material.

Sustainable Development and Sustainability

Sustainable Development and SustainabilityIn the decade of the eighties the concept of Sustainable Development was born defined as “that development which satisfies the needs of the present without compromising the capacity of future generations to satisfy their own needs”. Sustainable development is not an exclusively ecological concept, it can be assimilated as a equilateral triangle, the central area of which would represent the area of equilibrium between the social, economic and environmental component.

Sustainability, therefore, is a concept within sustainable development, which is referred to as “the quality of that which can be maintained by itself”, that is, the equilibrium of a species with its environment. The general criteria for sustainability are based on “Sustainability does not exist in maintaining intact the natural resources, but imply their efficient use, being necessary to introduce all the costs and benefits that the society needs to make”.

Sustainable architecture and sustainable materials

In the European Union, the construction of buildings consumes approximately 40 % of materials, generates 40% of the residues and consumes 40% of the primary energy* For this reason, it is important to promote sustainable architecture and sustainable materials.

In the area of architecture the norm ISO/TC 59/SC3 N 459 defines sustainable architecture as being “that which can moderately maintain the quality of life and harmonize with the climate, tradition, culture, the environment of the region, the time the energy and resources are conserved, recycles materials and reduces the dangerous substances within the capacity of the local and global ecosystems, throughout the lifecycle of the building”.

Architecture, in its environmental commitment to a more sustainable world, has the task of revising the relation between resources and residues and try to optimize it. The professionals of the sector should have the objective of tending towards sustainable construction, i.e., that which respects the environment, that optimizes its resources and materials, reduces the energy consumption, increases energy efficiency, the use of renewable energy, reduces wastes, reduces the emissions- in the concrete case of natural stone- emissions of CO2 to the atmosphere, minimizes maintenance and increases the quality of life.

The construction will become more ecological thanks to new systems of architecture and the use of recycled materials. To achieve this objective the choice of the construction material should be based on the realization of the evaluation of the following indicators:

• Trying to use existing natural resources in the area, i.e., use materials produced locally since the transport costs are reduced and wealth is created in the area.

• Use durable materials: the maintenance costs and wastage are reduced.

• Choose the materials the maintenance of which produces little environmental impact.

• Choose materials the production of which does not require too much energy.

• Try to use recycled materials: the problems of solid residues are reduced.

• Avoid using contaminating materials.

It is in this point that natural stone acquires significant importance, once one bets on construction with sustainable materials in a way that natural stone has a key role in sustainable architecture.

Sustainable materials. Qualitative analysis. Conditions

One understands by sustainable material that resource which is exploited below the limit of renewal. It is characterized by fulfillment of the following conditions:

• They comply with the “3 Rs”: Recycling, Reducing, Reusing. With respect to the stone products:

- Reducing. The reduction in the use of products, a clear example would be the aqueduct of Segovia, with 2000 years of extensive life of product, with minimum replacement.

- Reusing. Recovery of the useful fraction of material by means of extraction and reprocessing, so that the energy resources used for transformation of material are less since they avoid use of raw material.

The reusing in the use of stone products is a fact that can be observed in the cobblestones installed in the pavements of localities where they are reused, in the reusing of the ashlars and masonry of old buildings which in certain times of history were used as a “quarry” for new buildings, or in the recovery of building elements for their use in other buildings-rehabilitation of monuments-for example, materials to be thrown away. It is recommended to do testing to evaluate the loss of properties in the material.

Another example would be artificial stone, made of as much as 93% quartz, apart from glass, mirrors and polyester resins. These “remains” are pressed at high pressure and a constant temperature to obtain a new product. It is a short term solution since recycling these materials once finalized their useful life will mean treatment of separation of difficult to manage and expensive resins.

- Recycling. The process of elaboration of natural stone generates residues such as mud composed of refrigerated water of the gangsaws and grains of the rocks. The composition is the same as that of stone so it means there are no toxic elements. The residues are classified in mud treatment, cutting and polishing of stone. Once the codification and classification of the residues is determined one can determine how to handle them.

The evaluation of viability of the potential applications of the residues provides, apart from some environmental benefits, better use of resources, an increase of the production capacity and improvement in quality of product. This process of evaluation depends to a great degree on the properties of the residues, since technical specifications of the industrial uses are very precise. The biggest problems in making use of the residues are due to the chemical and physical composition and humidity. These residues are characterized by some parameters of diameter of particle which means a process of milling is required to achieve the size needed.

As the residues generated are basically formed of the varieties of stone in themselves, what are the products derived by these rocks are then determined, and what are their main uses. The industrial usage for these residues, mostly of those varieties that contain calcium carbonate due to their extensive industrial application, can, moreover, be residues of stone that are transformed into arid, applications in the calcium industry, that of cement, paper, paint, plastic, sealing and adhesives, pharmacy and cosmetics, carpets/ rubber, etc.

• Use of easily regenerating materials, which are those that grow or purify in natural way during a human scale period of time. A renewing resource can be depleted but with adequate administration, can last indefinitely. The level of consumption of stone with respect to the natural resources is very low so that it is possible to extend the activity almost indefinitely.

• Increase of useful life. The stone materials are resistant, lasting and attractive. Natural stone is, undoubtedly, the building material with most useful life.

• Reduction in use of Toxic Components. Stone does not require any chemical treatment during its useful life, as is the case with synthetic materials, metals, glass, etc. Stone goes through minimum deterioration due to atmospheric factors.

• Use of components and renewal or recycled energy. Both in the extraction phase as well as during processing, water is reused in closed cycles, pools, etc. avoiding this way the unnecessary use of water in the network.

• Minimize the visual impact on the ground. Among the environmental impact produced, though of temporary nature, is the disappearance of plants and trees. For this reason, the restoration and re-vegetation of the affected terrain due to these activities are considered among the main correcting measures that can be and are carried out in these projects.

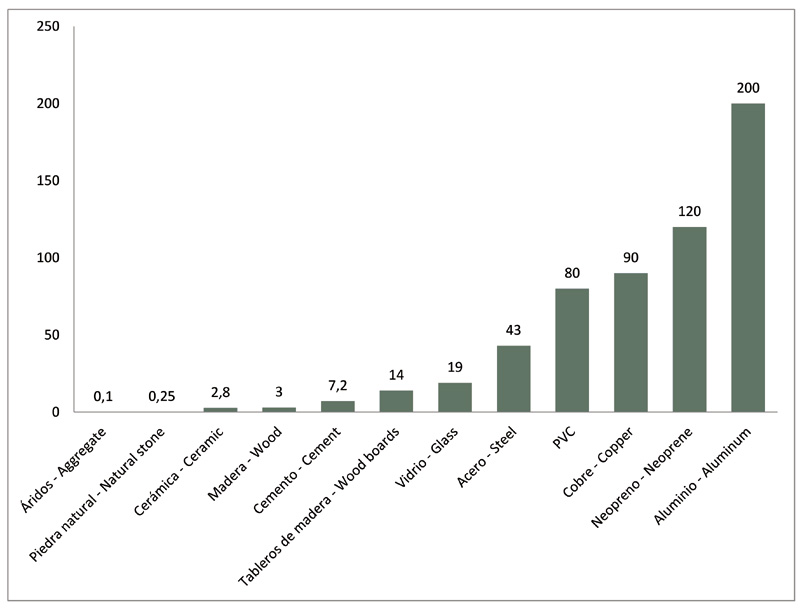

• Consumption of energy.** The energy costs corresponding to the extraction phase is approximately 0.175 MJ/kg, i.e., 70% of the total energy consumed. The energy costs corresponding to the phase of extraction is approximately 0.075 KJ/Kg, i.e., 30% of the total energy consumed. The total energy costs related to processing is low compared to the rest of the building materials, between 0.2 and 0.3 MJ/Kg. One should take into account that this total energy consumption is minimum if calculated with respect to the useful lifecycle of natural stone (MJ/Kg year of useful lifecycle) which can reach almost 0 owing to the large durability of the material.

Below one can see the comparative graph of the primary energy consumed according to the type of construction in the phases of fabrication/transformation of these materials.

From the architecture point of view it is a material that saves energy since it reduces the demand for energy of the building due its values of thermal conductivity, transmittance and thermal inertia.

• Atmospheric contamination. With stone no emissions exist that produce acidity in the atmosphere, nor are industrial elements dangerous for health used, neither are elements that are used on industrial scale that produce smog or which use CFC, etc. Natural stone, in essence, is inert.

Conclusions

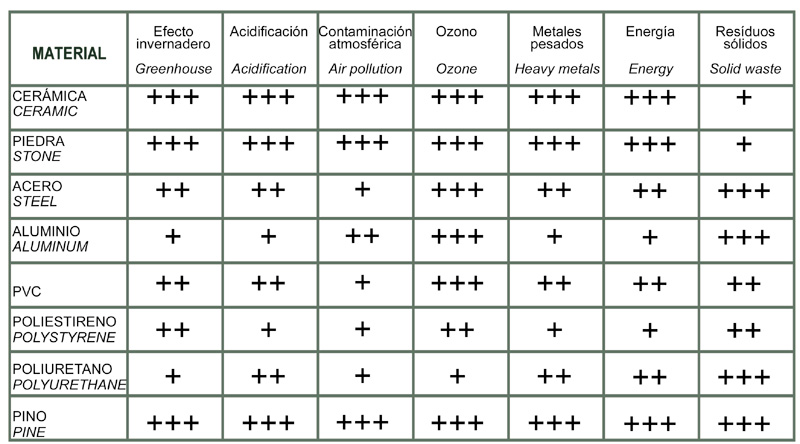

Below a table shows the environmental impact of the lifecycle of natural stone against other building materials.

One can conclude that natural stone is an excellent sustainable material, resistant, lasting, not toxic, fire resistant, reusable, recyclable, that does not need much maintenance, the lifecycle of which also means low energy costs, to which one can only attribute visual impact in the mining phase that can be corrected with strong norms of restoration for this type of extraction industries.

*(stone and sustainability. norms. Ángel G.Villanueva Hernandez, Technical session, ADE INVERSIONES Y SERVICIOS).

**(Source: Course “Bio-construction and sustainable materials, eco-union.org).

Sections