Eva Portas Fernández

Technical consultancy area Granite Technology Center www.fctgranito.es

Like any other building product, natural stone requires some controls to ensure its quality. The checks to be performed on stone products should be done in phases of manufacturing, supplying and reception at work and are, on the one hand, product liability and, secondly, responsibility of the Project Manager.

Production controls: CE marking

Since 2003, manufacturers of natural stone products are required to perform some checks on their production, related to CE marking, mandatory requirement for marketing in the European Union. For this reason, producers should implement a factory production control (FPC), consisting in laboratory tests with some frequency, to know the physical-mechanical properties of the material and, secondly, to control production dimensionally and visually. All this according to the European standards EN apply to each product.

After implementing this monitoring process, the manufacturer produces two documents: a Declaration of Performance (DoP) and a CE marking, which is affixed on the product.

Controls prior to delivery of stone

The heterogeneity of natural stone is sometimes matters of dispute between the contractor and the supplier as the expected look is not obtained once the work is complete. This is because the natural stone usually has variations of colour, texture, marbled, etc., associated with its natural origin and, moreover, need not constitute grounds for rejection.

In fact, many designers look to enhance the aesthetic value of the pavement from the variations in appearance. In general, it could be said that the variations in appearance along with a sufficiently harmonious laying can be a tool of architectural design, rather than a cause of rejection. Therefore it is necessary that, before delivery of the material, the manufacturer provides a reference sample consisting of at least four pieces and covering an area of at least 0,36 m2. The said sample must represent the extreme and average aspects of the material and must be accepted by agreement between the supplier, the project management and property owner. The criteria for acceptance or rejection of certain defects must be defined contractually between the manufacturer and the client before the start of supply. In general, following defects could be considered as grounds for rejection: broken pieces, pieces with cracks on some surface, pieces with breakage in the corner and breakage or chipping of the edges.

Pavement made with pieces of various shades in harmony

Controls at work site upon the reception of the stone

The proper use of natural stone requires a reception control work to ensure the provisions of the project. Different sampling systems can apply to inspect on site, during the reception of natural stone products. One of them is the standard ISO 2859-1:2012. Sampling procedures for inspection by attributes. Part 1: Sampling schemes indexed by acceptance quality limit (AQL) for lot-by-lot inspection. To implement this system, we have to consider, first, some issues explained below:

- The products received must be grouped in lots. A lot is the number of units sampled and it must be agreed before delivery between the supplied and the client, even specifying from project. Usually each delivery that reaches the worksite constitutes a lot.

- From each lot we will extract a sample, which is composed of a representative number of units of it. The sample will be taken from the lot, in general, randomly.

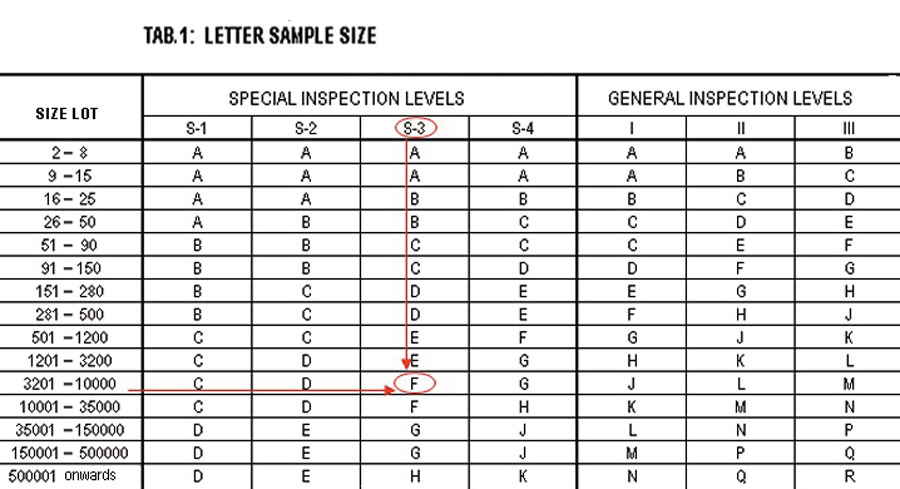

- The ISO standard provides a number of inspection levels: three levels of normal inspection and four special inspection levels, called S-1, S-2, S-3 and S-4. The inspection level recommended for natural stone is S-3.

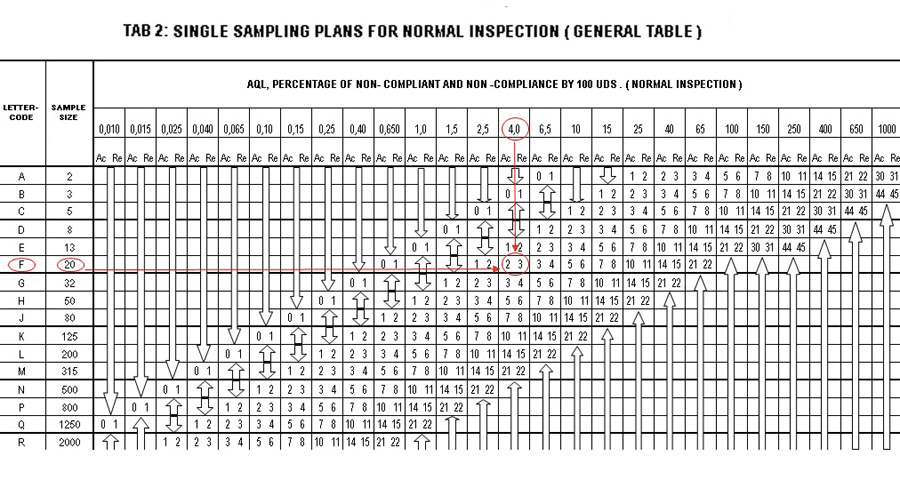

- Acceptance Quality Limit AQL (%):It is the average maximum percentage of non -conformities can be tolerated in a number of lots to be considered satisfactory. In natural stone the AQL used is 4%.

Knowing all this, to apply this system we use a set of normalized tables where the criteria for acceptance and rejection of products depending on the size of our lots located on worksite.

In Table 1, depending on the size of pieces that make our lot , and establishing a level of inspection S- 3, a letter code is shown. In Table 2, with the letter indicated in Table 1, the appropriate sample size to be drawn of the lot is provided. With this sample size and establishing a AQL of 4%, we set forth the criteria for acceptance and rejection of the lot.

For example: In Table 1, for a lot size of 5000 parts (marked in red) a letter F is set. Table 2 indicates that we draw from our lot a sample of 20 pieces. For an AQL of 4%, provided the following criteria: Ac 2 Re 3. This means that if two pieces are nonconforming , the lot is accepted and , if three parts are nonconforming , the lot is rejected.

So, knowing this system, controls that are recommended on the sample shall be at least the following, considering it should be a set of tests carried out quickly so as not to interrupt the work.

1. Dimensional controls: Should be inspected at least the length, width and thickness of the pieces , checking the dimensional tolerances specified in EN standard of each product.

2. Appearance: This control is important for the proper completion of the work. Should be chosen a sample consisting of a number of parts representing the extreme characteristics of the stone from the point of view of color, texture, discontinuities , etc. This sample should be placed in a display and daylight side and observe if agreed.

3. Water absorption test according to EN 13755 and flexural strenght test according to EN 12372: They are made in the laboratory. these two rapid tests that will show if the material supplied corresponds with the CE marking.

In addition to these controls, the head of the reception of the work products should ensure that they are properly documented with the CE marking, if applicable, and flawless manufacturing or transportation.

We can say that with this approach will benefit the management of the work, through testing, will have a truly representative parameters of the material calculation. And the manufacturer, who will verify the quality of their production will also benefit. And of course, the user will benefit from a product built with a controlled materials.

Sections