In the natural stone sector, environmental and economic challenges are increasingly interconnected. Among the main issues is the high volume of waste generated during extraction and processing — which in many cases can reach up to 70% of the stone extracted. In response to this scenario, Fravizel positions itself as a benchmark in the development of technological solutions that enable doing more with less: more value, more efficiency, with fewer resources, less waste, and less environmental impact.

Fravizel and the revolution in stone working

With over three decades of experience and a strong commitment to R&D, Fravizel has developed a range of products that directly address the principles of the circular economy. These solutions range from more efficient cutting to the valorization of by-products, allowing companies in the sector to turn limitations into new business opportunities.

Among the most notable equipment are:

🔹 ELECTRA Squaring Machines

Designed to increase stone yield right at the quarry face, these machines ensure more precise cuts, greater mobility, and better block utilization. They are compact, easy to move, and optimize time and resources during extraction.

🔹 Waste Transformation and Reuse Lines

Including Luna presses and Torus pebble machines, these solutions make it possible to transform waste into new commercially viable products: flooring, cladding, decorative or design items.

Doing more with less: the new normal

“Doing more with less” is more than a motto — it’s the driving force behind Fravizel’s innovation. With natural resources becoming increasingly scarce and the need to reduce environmental footprint, the company’s solutions offer:

- Greater energy and operational efficiency

- Reduction of waste during extraction and processing

- Valorization of waste into new marketable products

- Sustainable and competitive growth for the sector

As the company itself highlights:

"In the stone sector, everything can be used — from by-products found in sugar, toothpaste, and even makeup. The challenge is turning that reality into a competitive advantage."

Fravizel: an active part of the sector’s transformation

Fravizel is at the forefront of creating solutions that drive the transition to a circular economy model. The company’s continuous investment in technological innovation, combined with a sustainable strategic vision, makes it an essential partner for those aiming to grow more efficiently, safely, and in alignment with European environmental goals.

Come and discover these and other products at Marmomac, in Italy, from September 23 to 26.

______________________________________________________

FRAVIZEL: The Quarry of the Future - Digital and Green Transition with the Mobile Line

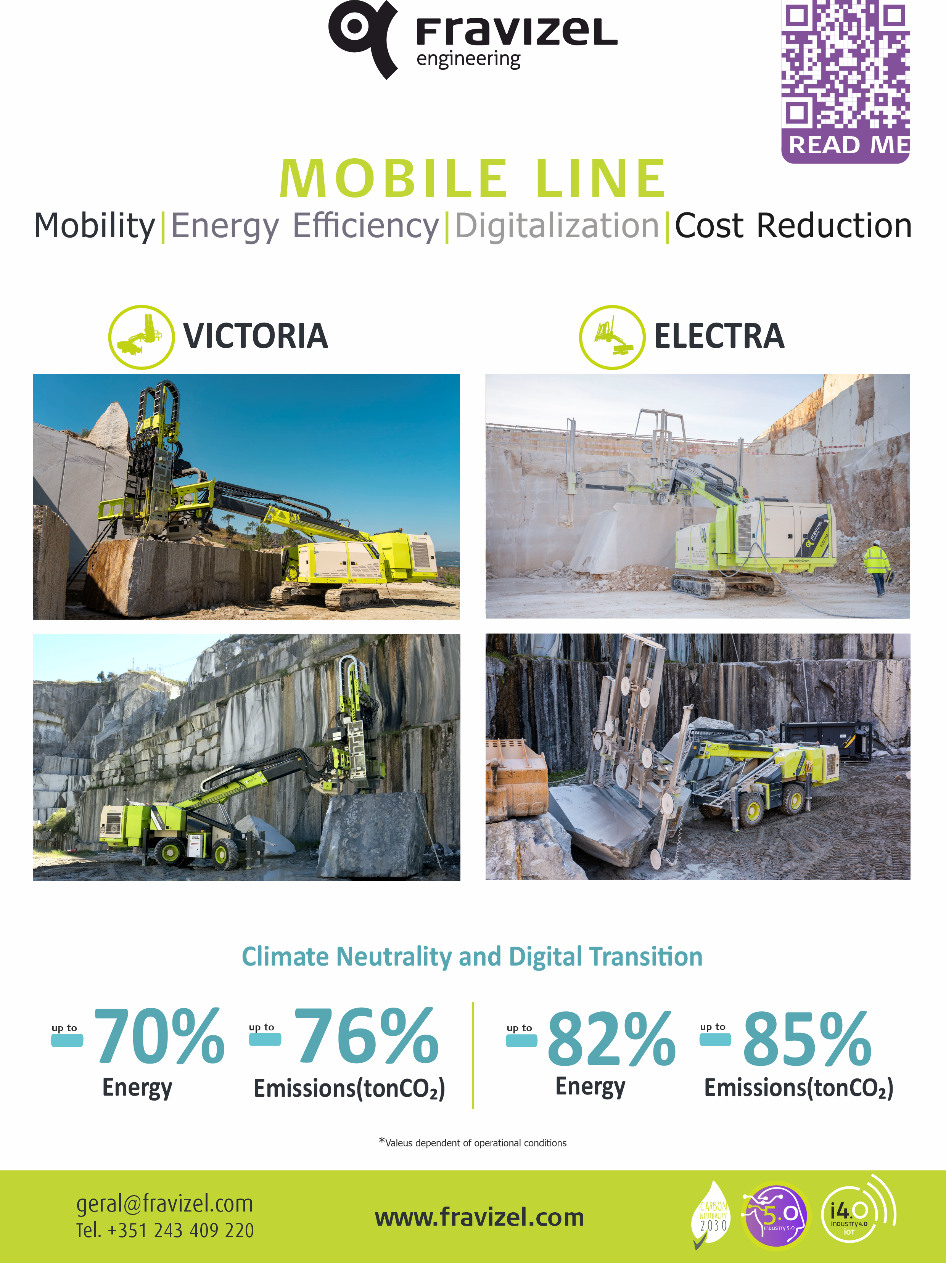

Fravizel, committed to providing innovative technological solutions for the extraction of ornamental stone, has stood out in the transition to a more sustainable and digital future. With the aim of increasing productivity and energy efficiency in quarries, the company has developed its Mobile Line, made up of autonomous wire and drilling machines known as Electra and Victoria. These machines, available in wheeled or tracked versions, represent a significant step forward in the European ‘twin transition’ aimed at climate neutrality and the digital transition.

The Mobile Line is designed to work in the squaring phase of quarries, where the felled benches are cut into transportable and marketable blocks. The Electra and Victoria machines, equipped with advanced technology, are remotely controlled and have telescopic booms with up to 7 different axes, allowing easy positioning of the cutting and drilling system.

Mobile Line Advantages:

- Innovative method with increased efficiency and productivity;

- Up to 7 axes for adapting to the workbench;

- self-propelled and fully autonomous;

- Capable of managing and storing data - cutting time, length, and height of cut (area), productivity control, using 4.0 technology;

- Individual hammer feed control system to optimise performance (Victoria);

- Victoria avoids up to 76% of CO2 emissions per year. The Electra avoids up to 85%.

____________________________________________

Fravizel and Industry 5.0: Increasing Efficiency and Safety in the Stone Sector

Fravizel, a reference in technological innovation in the natural stone sector, has accompanied the transition to Industry 5.0 by developing remote-controlled machines operable from within the cabin 4.0, with data monitored and managed through the Fravizel ON platform.

Fravizel machines are equipped with remote control systems, offering operators the ability to manage production processes remotely. This not only increases safety by preventing operators from exposing themselves to risk areas but also optimises the control and precision of operations. In addition, the cabins designed by Fravizel provide an additional layer of protection, allowing operators to work in extreme conditions without compromising their comfort and safety.

Figure 1 Fravizel’s Remote Control

These cabins are equipped with air conditioning and insulation systems, which maintain a comfortable internal environment, and visual panels that make it possible, through a camera system applied to the machine, to ensure that operators can carry out their duties effectively, regardless of external conditions. This combination of remote control and Cabin 4.0 reflects Fravizel's commitment to the safety and well-being of operators, while at the same time promoting more efficient and sustainable production.

Figure 2 Cabin 4.0

Fravizel ON is a platform that allows remote monitoring and the control of extraction processes, offering safe and effective management. With detailed information on machine performance and productivity, the platform enables agile and informed decision-making. This not only increases operational efficiency but also improves the safety of operators, who can avoid risk areas while maintaining control over the production process. By transforming data into knowledge, the platform not only improves production but also contributes to building a more responsible and technologically advanced industry.

Figure 3 Fravizel On

By adopting technologies that reduce emissions and promote the circular economy, Fravizel is not only protecting the environment but also creating a more efficient and sustainable production system.

The use of remote technologies that speed up operations and turn data into knowledge reflects the technological innovation typical of Industry 4.0, but Fravizel's focus on workers' well-being through safe and inclusive environments and personal empowerment aligns perfectly with the goals of Industry 5.0.

Thus, Fravizel not only improves efficiency and safety in the natural stone sector but also promotes a production model that values people and the planet, showing how technology can be used to create a more sustainable and humanised future, central characteristics of Industry 5.0.

____________________________________________

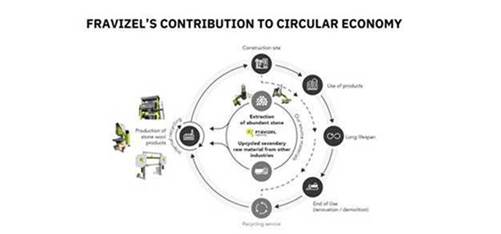

Circular Economy in the Natural Stone Business: A Path to Sustainability

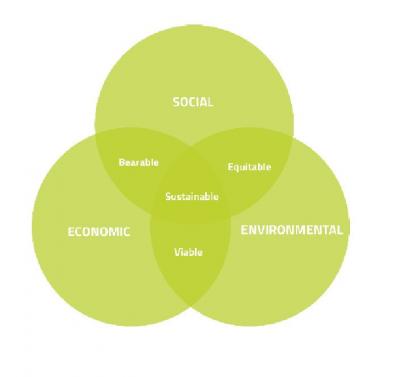

Circular economy means being sustainable. At Fravizel, we strive for sustainability across three dimensions: environmentally, socially, and economically.

Innovating implies investing many resources. Circular economy emerges as an opportunity, allowing us to achieve what was previously unthinkable. Some of the main challenges in this industry are sustainable supply, environmental footprint, digitization, and safety measures.

Circular Economy involves reducing inefficiency through material and energy reuse, playing a crucial role in boosting the economy and ensuring the planet's sustainability.

The stone sector offers vast utilization possibilities, including by-products used in various industries like sugar and cosmetics. We aim to transform companies into more efficient ones by seizing this opportunity.

Companies must develop innovations aligned with European strategies, focusing on environmental efficiency and reducing energy consumption while launching new products.

Fravizel has launched hybrid technologies like Electra and Victoria, enabling high energy efficiency and greater productivity. These machines allow for increased quantity and quality of extracted stone, along with stone processing machines (such as Toros and Luna) focused on creating new, high-value products.

We are committed to adapting to a constantly changing environment, focusing on safe, sustainable growth with maximum use of raw materials and green energy.

Let's innovate sustainably, leveraging new technologies to drive the industry forward while respecting the planet.

____________________________________________

Why FRAVIZEL machines will make your quarrying more ecological sustainable

Stone is a perfect example of a sustainable product, and its method of exploitation can be too. It is possible to be ecologically sustainable in quarries, did you know that?

In order to achieve the goals of the European environmental pact, various measures have been taken at a social, economic and environmental level, a can be seen in figure 1.

Fravizel is an engineering company whose main objectives are the development of technology to reduce operating costs and increase productivity, carbon neutrality, hybrid technology and digitalization with working conditions and safety for the workforce. This is why it has focused on developing innovative technological solutions that comply with good environmental, social and business management (ESG) practices.

Fig.1: Sustainability model

Source: Fravizel, 2024

We make the operator's job easier by providing good conditions, safety and technological attractiveness (Social Sustainability). Our products promote the circular economy and hybrid technology, while protecting the environment (Environmental Sustainability). Innovation at a high level for good time management and productivity (Economic Sustainability).

Allowing for a sustainable increase in productivity through equipment that intervenes in all the necessary phases of stone extraction. Our machines are developed to meet every need, with maximum efficiency and resource management. As you can see in figure 2.

(compared with traditional methods)

Fig. 2: Machine diagrams for each extraction phase

Source: Fravizel, 2024

For "making it happen fast", the mobile and Aurora Line are examples, consisting of drilling and diamond wire machines (Victoria and Electra) on wheels or tracks, for the squaring phase. Based on European objectives, this line of machines was designed with the "double transition" of climate neutrality and the digital transition in mind. These machines avoid up to 87% of CO2 emissions per year and more than 80% in energy costs.

![]()

FRAVIZEL Metalomecânica e Engenharia (Portugal)

See our Natural Stone catalogue here