Sini Laine, executive director, KIVI - Stone from Finland, sini.laine@kivi.info

Olavi Selonen, director of development, KIVI - Stone from Finland, olavi.selonen@icloud.com

INTRODUCTION

The natural stone industry is a very traditional branch of industry in Finland. The oldest, still operating company, is Kiviveistämö Berglöf Oy, founded in 1896, and producing gravestones and headstones. The fifth generation is now running the company. The oldest quarrying company is Finska Stenindustri Ab, from 1900, and operating today several quarries in southern Finland. The company Tampereen Kovakivi Oy (Suomen Graniitti Oy) was founded in 1914 in the city of Tampere in south-central Finland and quarrying and processing currently the popular Kuru Grey granite among other local granites. Palin Granit Oy (a member of WONASA) was formed in 1921. At the beginning, the company produced mainly gravestones and monuments, then diversified in construction, but is now focusing on quarrying with several quarries in southern and central Finland. Loimaan Kivi Oy (1921) was initially part of Palin Granit Oy, but went independent in 2012, and is today by turnover the largest granite company in Finland with eight quarries and three processing plants. Currently, there are six companies dedicated purely to quarrying granites.

Granites are extracted mostly in south-central Finland in the Pirkanmaa district north of Tampere (the villages of Kuru and Kapee: grey granites) and in southeastern Finland south of the city of Lappeenranta (the rural centre of Ylämaa: brown, green, and black granites, and the municipality of Virolahti: red granites). Other production centra are the village of Korpilahti (black and red granites) and the municipality of Viitasaari (grey, red, and black granites) in central Finland.

There are approx. 250 actively operating companies in the natural stone industry in Finland, mostly SMEs, producing stone for domestic market and for export. The main export countries in 2024 were China, Lithuania, Italy, Poland, and Egypt. The annual turnover of the industry is nearly 200 million euros. The stone industry employs directly approx. 1000 persons.

The association KIVI – Stone from Finland (formerly the Finnish Natural Stone Association), founded in 1938, is the sole association representing companies operating in the natural stone industry in Finland. KIVI has 57 member companies, 19 partners, and 50 student members. KIVI is a member of Euroroc, Green Building Council Finland, Suomen Yrittäjät (an interest and service organization for small and medium-sized enterprises, SMEs) and the Association for Finnish Work. KIVI’s mission is to increase the demand and the awareness of the natural stone as a low carbon footprint construction material. KIVI aims to enable the best possible business environment for the member organizations.

In this article, we highlight the production of granites in Finland.

COLOURS OF GRANITES PRODUCED IN FINLAND

Baltic Green granite

Kuru Grey granite

Savo Pearl granite

Grey granites

Kuru Grey is a fine-grained, non-foliated, equigranular grey granite. It is suited for all interior and outdoor uses, and especially well for products with split surfaces such as environmental stone and paving stone.

Today, the granite is extracted in six active year-around quarries, which are located approx. 50 kilometres north of Tampere. Kuru Grey is well-known among the stonemasons in Europe. Currently, it is the most popular stone in Finland, used domestically and exported to Poland, the Baltic States, Japan, Sweden, and Scotland.

Quarrying for Kuru Grey granite. Photo: Paavo Härmä.

Brown granites

Brown has been the most popular colour from Finland and the material Baltic Brown is well-known in the industry and among architects and interior designers of the world. Baltic Brown is a brown, coarse-grained, non-foliated granite with a texture of individual, round 15‒50 mm K-feldspar crystals with a greenish plagioclase mantle. The colour and appearance of the stone vary somewhat depending on the quarry. The granite is extracted from several quarries in southeastern Finland, approx. 40 km south of the city of Lappeenranta. It is suited for all interior and outdoor uses, also for big projects. The lighter shade of brown is called Baltic Brown Light/Baltic Grey. Baltic Brown is exported mostly to China, Middle East, and Pakistan.

Red granites

Carmen Red/Karelia Red (designation depends on the quarrying company) is defined as deep red, porphyritic, coarse-grained, non-foliated granite with individual, relatively large, usually round K-feldspar grains, ranging from 20 to 40 mm in diameter. The colour variations of the granite are small; occasional shades of pale red occur. Carmen Red/Karelia Red granite is extracted from several quarries in southeastern Finland, approx. 70 km south of the city of Lappeenranta. The stone is exported to China.

Another red-coloured granite from southeastern Finland is Eagle Red. Balmoral Red fg and Balmoral Red cg are in turn traditional, renown Finnish red granites quarried from southwestern Finland.

Green granites

Baltic Green is a green, coarse-grained, non-foliated granite with individual, round K-feldspar crystals, ranging from 15 to 30 mm in diameter. The granite is suited for all interior and outdoor uses. There are two quarries of this granite, situated in southeastern Finland, not far from the Baltic Brown quarries. The stone is exported to Poland and the Baltic States.

Multicolour granites

Aurora is medium to coarse-grained, oriented migmatite with red and black as the main colours. It has a wave-like “flame” pattern. It is suited for all indoor (tabletops, worktops, and interior design) and outdoor uses (especially environmental constructions and building projects). It is also popular material for manufacturing monuments and gravestones. The quarries are situated approx. 60 km north of Helsinki and the granite is produced since the 1980s.

Aurora has recently been used in metro stations in Helsinki and other public projects of the city such as extensively in the Kalasatama area (see below). The stone is exported to the Baltic States, Poland, and Germany.

Black granites

There are several small black quarries in Finland. Varpaisjärvi Black is one of the most important black qualities. It is a fine-grained and uniformly black diabase. Quarries are situated in eastern Finland. It is most often used as tombstone and environmental stone, but also as a decorative stone, mainly as tabletops. Another significant production district is Korpilahti (Korpi Black). At the moment, the black granites are used only domestically.

USE OF GRANITE IN FINLAND

The blocks extracted in the Finnish granite quarries are further processed either domestically or abroad. Granitic end products are used, e.g. as slabs in the façades of buildings, in interior design, monuments, stairs, street paving, as well as in environmental construction.

One of the latest projects of exported Finnish stone is the development of the Martin Place Metro Stations in central Sydney, Australia. A significant building at the Martin Place, the Commonwealth Bank building, was erected in 1916. The façade of the building is made in Finnish Balmoral Red fg granite. The same colour scheme was sought after when building the Metro Station North and South Towers close to the Commonwealth Bank. The high ground floor of both towers is now clad with Balmoral Red cg granite, extracted close to the Balmoral Red fg. Palin Granit Oy extracted approx. 1000 m3 granite for the project, which were completed in 2024.

During the recent years, a clear increase in use of Finnish granite in domestic market has been seen because of high quality of stone and low carbon impact compared to imported stone (see below). Currently, there is a good demand, e.g. for (grey) kerbstone. Two interesting domestic projects can be mentioned: the Kalasatama (“Fish Harbour”) district in Helsinki and the Tampere light rail in Tampere.

Kalasatama is a huge renewal project in the eastern inner city of Helsinki. It comprises a substantial part of a former harbour area, on which a new large residential and office area is built. According to Mikko Paljakka, managing director of Loimaan Kivi Oy (stone manufacturer), approx. 25 000 m2 of paving slabs, approx. 15 000 m2 of cubes and setts, approx. 15 000 linear metres of kerbstones, approx. 1 000 linear metres of stairs, approx. 8 000 m2 of masonry (mostly as seawalls with rock-faced surface), and approx. 5 500 linear metres coping stones for masonry, is laid in the Kalasatama area. Several Finnish stone qualities are used in this area, the most applied are the multicolour Aurora migmatite, the Varpaisjärvi Black diabase, the Balmoral Red cg granite, the Ristijärvi Grey granite, the greyish Viitasaari Light granite, and the Korpi Black gabbro.

Granite is applied extensively in the Kalasatama area in the city of Helsinki. Photo: Sini Laine.

The Tampere light rail, called the “Tampere Tram”, is a public transport system operating from the city centre of Tampere to suburbs. Construction of the tramway started in 2017 and is continuing. At the Hämeenkatu Street (the main street of Tampere), natural stone is used as paving in the superstructure of the tramway. Equal amounts of different granites from the Kuru granite quarry district (Kuru Grey, Kuru Redbrown, Kuru Black) are applied as dimensioned setts. Antti Elomaa, managing director at the company Tampereen Kovakivi Oy (manufacturer of the stones), says that the total amount of the Kuru granites applied in the superstructure of the Tampere tramway is approx. 15 000 m2. Furthermore, approx. 5 000 linear metres of kerbstones in Kuru Grey is used in construction of the tramway stations.

Local granites from the Kuru granite district was used while building the light rail in the city of Tampere. Photo: Pasi Tiitola / Tampereen Raitiotie Oy.

One of the most spectacular monuments of recent years is the memorial to Martti Ahtisaari (1937–2023), the former president of Finland and the recipient of the Nobel Peace Prize in 2008. A block of size 5 x 2 x 1.5 m in Baltic Green granite was quarried by Palin Granit Oy and processed by Loimaan Kivi Oy. The memorial, designed by architect Harri Pakarinen, is located at the Hietaniemi Cemetery in Helsinki and was unveiled November 10, 2024.

Memorial to President Martti Ahtisaari in Baltic Green granite. Photo: Paavo Härmä.

QUARRYING IN THE COLD

The quarrying of granite is done year-around in Finland, but once the temperature goes below -22ºC, the quarrying activity must be halted - at this point, the machines start breaking down due to the metal getting brittle, though human beings are perfectly capable of going on. During winter, the machines need around 30 minutes to warm up, that is the time the lubricants need to get flowing. In addition, the flushing water for diamond wire saws can freeze down.

Granite is quarried all the year round in Finland. Photo: Palin Granit Oy.

ENVIRONMENTAL ISSUES

In Finland, quarrying of granite is ruled by the Land Extraction Act, and a land extraction permit, and an environmental licence is acquired. One important criterion for getting permits is that there should be no houses to a distance of at least 300 metres from the quarry independently of whether the land is owned or rented by the company wanting to undertake extraction activity. Permits are usually granted for 10 years though according to the law they can be up 15 or 20 years, and the permits are usually renewed.

In recent years, the Finnish natural stone industry has invested extensively in developing environmentally sustainable production in both stone quarrying and processing. First, we carried out a study on the environmental impacts of quarrying (noise, dust, vibration, water, radiation, left-over stone, LCA), then a study of best environmental practises (BEP) to manage the impacts. These studies are unique in Europe, if not in the whole world.

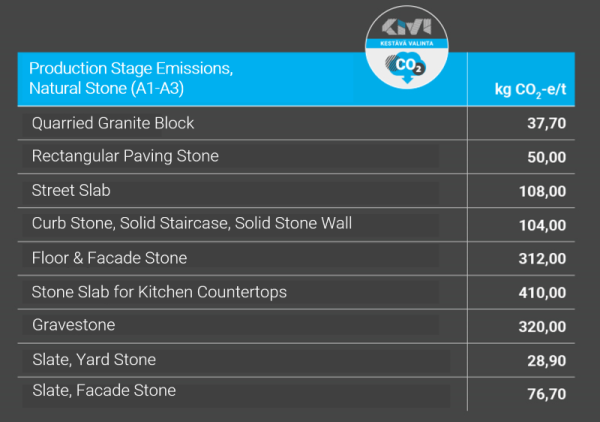

Carbon footprint of Finnish natural stone

In the 2020s, we have focused on examining the carbon footprint of Finnish natural stone. The project covered natural stone building materials for the focus product groups EN 15804 and ISO 14025 (European Standards). The environmental product declaration (EPD) covers the life span of the natural stone produced in Finland from the quarry to recycling. Verified EPD Documentation was carried out for dimensioned blocks, setts, paving slabs, kerbstones, masonry, stairs, floor stones, façade stones, kitchen tops, gravestones, schist for yards, and schist for façades. Stone types were granite and schist.

Why the EPDs? The public sector in Finland requires the verified documents of the materials carbon emissions. The Environmental Product Declaration provides data about the environmental impacts of a product through the product life cycle. In Europe, EPDs must conform to the European Standard. This ensures that EPD for construction products use a common methodology, report a common set of environmental indicators, and have a common reporting format. EPD can be integrated into building level assessment and used to compare construction products in a building context. New, upgraded EPDs will be completed in 2025 for the same product groups as before.

EPD

All results of the environmental studies can be found at the website of KIVI – Stone from Finland (https://kivi.info/kivi-ry/kivi-stone-from-finland/).

CHALLENGES OF TODAY

The export of Finnish granite has decreased due to the slowdown of the Chinese market. In addition, the low activity of construction in the world and the current unrest (wars, conflicts etc.) in many countries are challenging the natural stone market. Furthermore, materials like ceramics have taken a bigger part than before of the market for natural stone, tells Heikki Palin, managing director of Palin Granit Oy.

The Finnish granites are traditional regarding colour and appearance. Hence, there is a need for new interesting qualities of stone with a special strong colour (blue, white) or a special outlook of vivid and variegated structure. However, today it is expensive to open a new quarry due to high access costs: several assessments (regarding nature values, noise, dust, water management etc.) are needed before the permits can be granted. Furthermore, the cost of authorities handling the permitting process is high. These circumstances indicate that only companies with strong economy can employ this activity.

A challenge for all quarry operators in Finland (and elsewhere in Europe) is how to add value to material that is not commercial blocks, i.e. the leftover stone. Besides the possibilities created by the concept of circular economy, potential for increased use of the leftover could be found in product development based on, e.g. the functional properties of the leftover, or in promoting solutions, e.g. for breakwaters and other structures instead of endorsing bulk material. In Europe, the leftover stone is legally classified as waste, which challenge its use. Creating the end-of-waste criteria for the leftover stone as soon as possible would be an important part of enhancing the use of the leftover.

Acknowledgments

Mikko Paljakka (Loimaan Kivi Oy), Heikki Palin (Palin Granit Oy), and Antti Elomaa (Tampereen Kovakivi Oy) kindly helped us to compile this article.