By Mohamed M. ElBatran, Architect, Deputy General Manager, HAZ MARBLE EGYPT

On Saturday, November 1, 2025, the Grand Egyptian Museum (GEM) was officially inaugurated on the Giza necropolis plateau, adjacent to the iconic pyramids. Dubbed the ‘Fourth Pyramid,’ the GEM is now the world's largest archaeological museum dedicated to a single civilization, spanning approximately 490,000 m². It is projected to welcome around 5 million visitors annually.

In this monumental achievement, natural stone was the undisputed star. The project's complexity demanded the participation of highly qualified companies to execute the ambitious vision.

Project Leadership & Design

The building's design was conceived by architects Róisín Heneghan and Shi-Fu Peng of Heneghan Peng Architects (Ireland), in collaboration with Buro Happold, Arup, and ACE Consulting Engineers. The landscape master plan was designed by West 8, while Atelier Brückner led the exhibition masterplan and design.

The project was managed by a joint venture between Hill International and EHAF Consulting Engineers. Key representatives included:

The Client (Ministry of State for Antiquities, represented by the minister, Supreme Council of Antiquities (SCA) and Engineering Authority of Armed Forces (EAAF)) represented by:

Major General Atef Moftah – General Director of Grand Egyptian Museum Project and Surrounding area / Director of Engineering Committee of Engineering Authority of Armed Forces

The Contractor BOJV (Besix-Orascom) represented by:

Mr. Joris De Kinder – Project Director.

Mr. George Kyrillos – Dep. Project Director.

The Consultant (PMC is a JV between Ehaf and HILL international) represented by:

Mr. Huibert Vos - Project Manger

Mr. Ayman Heikal – Dep. Project Manger

The Primary Stone Specialist HAZ MARBLE

represented by:

Mr. Abit Yesilkaya. – Founder & CEO of HAZ Group / Project Director

Mr. Mohamed ElBatran – Dep. Project Director

HAZ MARBLE was responsible for 190,000 m² of the stone delivery and installation on site.

HAZ MARBLE 's scope was comprehensive, including:

Designing, procuring, and installing the stone and steel substructure for approximately 190,000 m² across the entire project.

Supplying all fixing systems through HAZ METAL.

Procuring and managing mega steel substructures through qualified local suppliers.

Sourcing the Stone:

The project team prioritized local Egyptian materials, making them the heart of the museum's aesthetic:

HAZ supplied all the 190,000m2 of stone through local suppliers and manufacturers under the supervision of Haz Marble, with very minor imported materials like Double Black & Galaxy granite used on a small scale for specific areas, one of the major HAZ suppliers is MARMONIL which supplied a total of 70,000 m² of these local stones for the museum's interior.

Verdi Ghazal (Egyptian Granite): Used mainly for flooring and toilets cladding

Teriesta/Sinai Pearl (Egyptian Limestone): Used for the cladding and landscape flooring works.

Black Aswan (Egyptian Granite): Used for vanity tops.

Double Black & Galaxy granite: Used for hanging obelisk, some corridors and some water features.

Technical Excellence and Innovation

The HAZ Technical Office played a critical role in translating the design into reality:

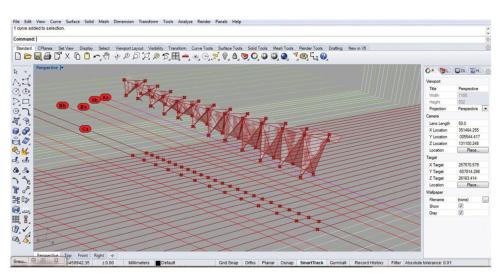

BIM Integration and extraction: The scope of work was extracted from the BIM model, and this data was used to create precise shop drawings, technical notes, fixing orders and cutting lists.

Technical Leadership: HAZ prepared technical notes for works executed on steel structures and provided drawings that were also used by other stone subcontractors.

Precision Fabrication: They supplied and applied cut-to-size stone where needed and supervised all on-site operations.

Overcoming Monumental Challenges

The project presented several unique engineering and installation challenges, which HMMJV successfully overcame:

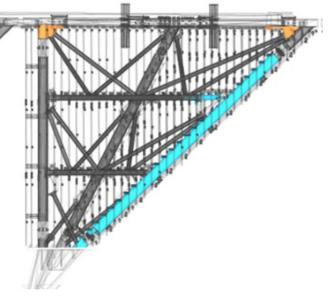

Inclined Steel Structures: Cladding the main building's north facades and conference building north and south facades, which consist of concrete beams, required a custom-designed steel substructure to mechanically fix the Teriesta limestone.

The "Stilettos" (Mega Pipes): Three massive structural pipes were transformed into a three-faced cone, with two faces mechanically clad with Teriesta stone, based on HMMJV's substructure design.

Grand Stairs: Installing massive Verdi granite slabs (1494mm x 640mm, 110mm thick) on post-tension precast concrete beams.

The Hanging Obelisk: Cladding this unique architectural feature with engraved Double Black stone.

Through this combination of local natural beauty, technical innovation, and expert execution, natural stone has rightfully earned its place as the protagonist of the Grand Egyptian Museum, ensuring a timeless legacy for this modern wonder.

GEM Tourist Walkway

GEM Walkway is a distinct project 2 km long walkway connecting the Grand Egyptian Museum (GEM) to the Pyramids, MARMONIL's supplied 41,000 m² of stone material with HAZ MARBLE responsible for the technical execution and installation works of the walkway.

-The Contractor is Orascom construction

-The Design concept & supervision by Major General Atef Moftah – General Director of Grand Egyptian Museum Project and Surrounding area / Director of Engineering Committee of Engineering Authority of Armed Forces

-The consultant and structure designer is ACE [ Arab Consulting Engineers (Moharram - Bakhoum)