Alexandre Franco - AKEMI Brasil

CEO & Technical Responsible

Before we delve into the subject, it is important to understand a bit about rocks and the reasons for their occurrence

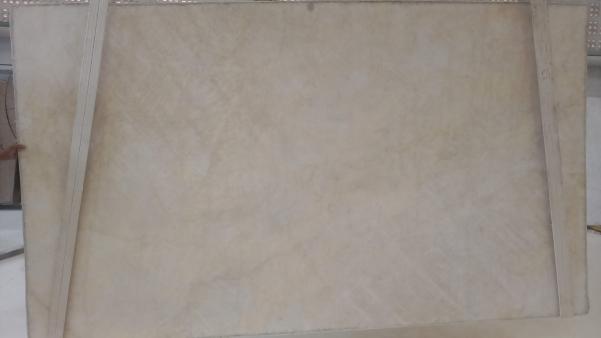

The quartzites available in the market may be classified as either quartzite or metarenite, both of which are highly similar types of rock. They are characterized by their exceptional durability, versatility, and aesthetic appeal, which contribute to the value and sophistication of various projects. However, like any material, each possesses distinct characteristics that, when respected, position this type of rock as one of the most optimal options in the market for a multitude of applications.

The fundamental distinction between them resides in their formation processes, which result in varying characteristics and numerous textures. These differences include the following:

• Metarenite exhibits greater toughness and enhanced resistance to compression.

• Quartzite demonstrates superior resistance to scratches and chemical attacks.

• Metarenite is characterized by a higher porosity and absorbent nature.

To talk about solutions to problems that may occur, we will divide them into two categories: Natural characteristics and external agents.

Natural characteristics can be: organic contamination, coming from nature itself, or metallic compounds in its composition.

Organic contamination can be treated by applying a fungicidal agent before the removal of metallic materials, as this process can interfere with the oxidation of the same.

Metallic compounds can be almost eliminated by acid attack during their industrialization process, but always following the sequence below:

1° apply the acid to the sheet and wait for the reaction that will solubilize the metallic compounds;

2° wash the sheet well to remove the soluble salts generated by the reaction;

3° neutralize the acid residue on the sheet to avoid delayed reactions and the formation of an environment favorable to the proliferation of fungi.

It is important to remember that acid treatment by immersing the slabs, although very efficient in dissolving the metallic compounds inside the sheet, can generate future problems if the washing and neutralization do not have the same penetration and efficiency as the acid attack.

If washing and neutralization are not efficient, a certain amount of solubilized salts may remain inside the plate and its pH may be slightly acidic.

The residual salt can subsequently hydrate and increase in size, creating internal pressure that can cause flaking and even damage to the resin used.

The slightly acidic pH creates an ideal environment for the formation of fungi, which procreate more easily in this condition.

External agents are a common problem for any coating and can occur due to: humidity (rising, descending and condensation), attack by staining/chemical agents (sauces, drinks, unsuitable cleaning products, etc.).

To prevent or minimize damage caused by external agents and to facilitate cleaning, it is essential to protect the tile on all sides.

For the back of the tile, waterproofing products should be used, which form a film and prevent the passage of both water and water vapor. This waterproofing will prevent rising damp, condensation or even the mortar mixture itself from contaminating or reacting with components of the rock.

The sides and surface should be treated with a good quality of iimpregnators agent, impregnating completely the rock, thus making it difficult for staining materials to adhere or react.

An important observation is that some products on the market, indicated for use on the back, are water repellents, usually silane/siloxane based. These products provide temporary protection, only protecting the rock from contamination by the water in the mortar. For all the other situations mentioned above, these products are not effective after some time.

For proper maintenance, daily cleaning should preferably be done with neutral detergent and low-abrasion utensils and equipment, which preserve the protective product for much longer. For heavier cleaning, an alkaline detergent can be used if possible and low abrasion utensils and equipment.

Although Quartzites and Metarenites are resistant to acids, the use of acidic cleaning materials normally removes the water-oil repellent, which must be reapplied at the end of cleaning. Regarding stains, we can use different products for different situations, which must be analyzed on a case-by-case basis, always remembering to give preference to the least aggressive processes.

Special thanks to Mr Reoenison (Rhoy) Herculano, for his support in the research and development of industry processes.